Air & Gas Management Solution

Assets We Track

- Pressure sensors

- Flow meters

- Compressed air systems

- Gas storage & distribution

- Steam generation & boilers

Quick issue identification

Cost reduction

Risk prevention

Downtime reduction

Regulatory compliance

Enhanced safety

Implementing advanced monitoring solutions for compressed air, compressed gases, and steam systems is essential for maintaining operational efficiency, ensuring safety, and minimizing energy consumption. Leveraging IoT and AI technologies, these systems provide real-time insights, predictive analytics, and automated controls to optimize performance and reduce costs.

Air Management

- Track parameters such as pressure, flow rate, and energy consumption to identify inefficiencies.

- Utilize IoT-enabled sensors to detect air leaks promptly

- User-friendly interface with real-time data, historical trends, and system diagnostics.

- Receive automated notifications for preventing unexpected downtimes.

Gas Management

- Detect particulate and microbial contamination, ensuring gas purity and compliance.

- Track gas flow rates and pressure levels in real-time.

- Generate reports adhering to regulatory requirements.

- Maintain comprehensive records of gas quality and usage patterns.

Steam Management

- Assess steam purity and dryness to ensure efficient heat transfer and process reliability.

- Monitor steam generation and distribution

- Maintain optimal pressure and temperature levels.

- Utilize data analytics to forecast maintenance needs and prevent equipment failures.

Features

Real-Time Performance Monitoring

Leak Detection & Prevention

Centralized Dashboard & Analytics

Predictive Maintenance Alerts

Energy Consumption Analysis

Contamination Detection

Flow and Pressure Monitoring

Automated Compliance Reporting

Integration with Existing Systems

Data Logging and Trend Analysis

Steam Quality Monitoring

Energy Usage Tracking

Pressure and Temperature Control

Condensate Recovery Optimization

Predictive Maintenance Scheduling

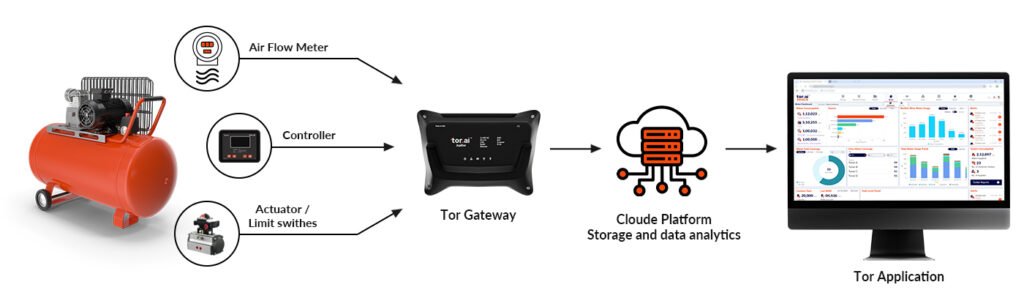

Architecture

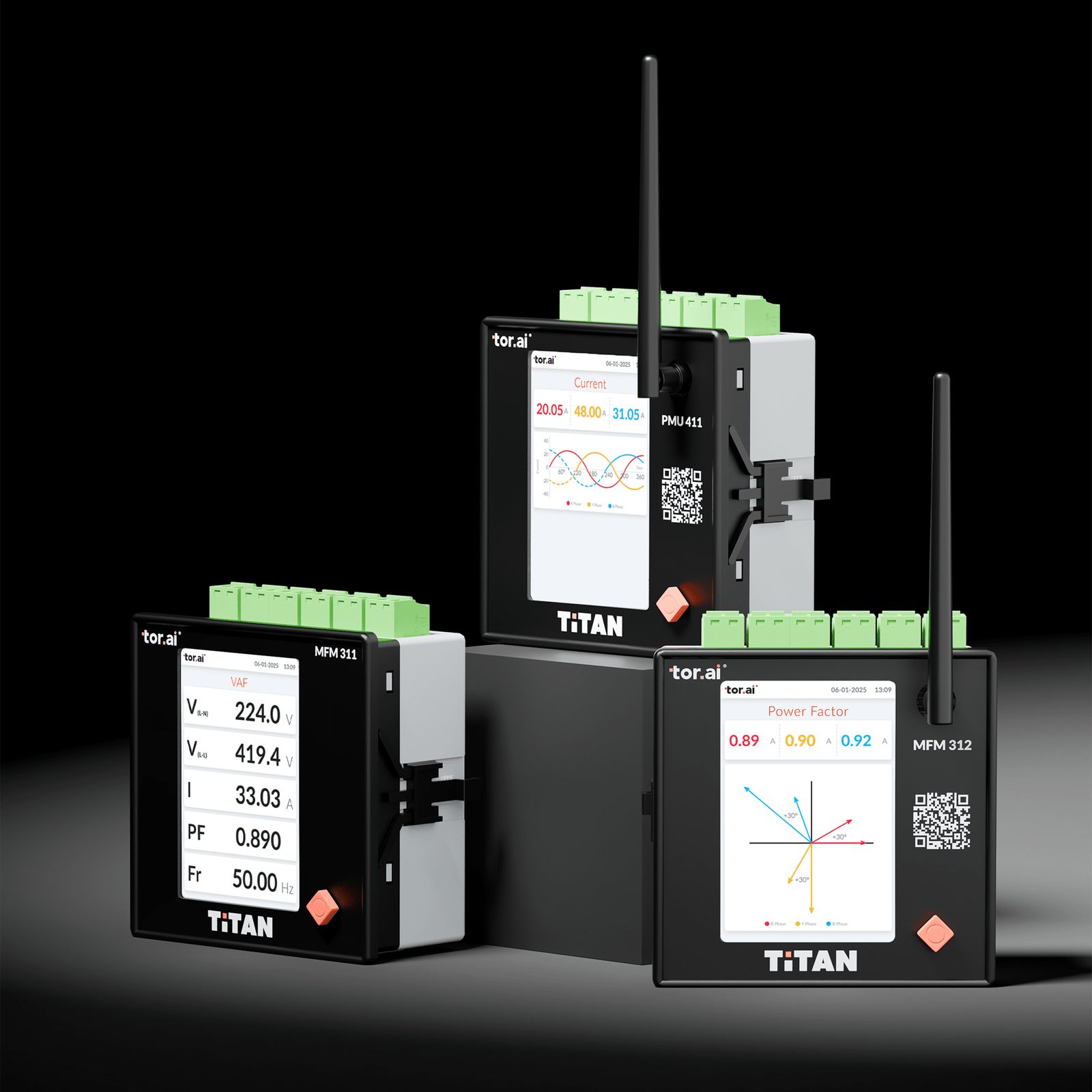

Energy Meters

Tor Titan is a compact power monitoring unit that tracks 68 electrical parameters, including power quality and harmonics, with advanced transient analysis. With advanced connectivity, scheduling, and PLC functionality, it integrates seamlessly into industrial IoT systems for efficient and reliable performance.

Temperature sensors

Tor Mercury is a high-temperature, long-life wireless sensor built for extreme environments. It is suitable for temperature monitoring of bus bar trunking & distribution panel systems. Its 240°C resilience, 15-year battery life, and BLE connectivity enable seamless IoT integration, faster installations, and reliable performance with minimal maintenance.

Gateways

Industrial application device having 4G LTE Cat1 connectivity with flexible communication protocol support and flexible Inputs along with a high capacity battery backup