APFC panel monitoring

- Capacitor bank

- APFC relay

- Multifunction meter

Cost reduction

- Alerts for low power factor

- Power quality analysis

- Capacitor bank size optimisation

Manpower optimization

Enhanced response time

- Whatsapp / Email alerts for all deviations

- Push notifications

- Flexibility to set deviation levels for alerts / warnings

- Quick RCAs through INVESTIGATE feature

Quick issue identification

- Bird’s eye view of multiple locations / assets on single screen

- Comparative trend analysis

Efficient MIS / reporting

- Benchmarking across locations / assets

Downtime reduction

- Error free data logging

- Spotting early failures

- Predictive maintenance

- Resource planning (Spare parts, maintenance manpower)

Compliance

- ESG and sustainability reports

- CO2 report / consumption split by source

Real-time APFC panel monitoring ensures efficient reactive energy management, improving equipment longevity and reducing costs.

key Features

Demand and Supply analysis

- Know whether the current APFC panel has the capacity to meet the required reactive power (kVAR) demand

- Track status of capacitor bank steps and reactive power demand pattern to match it with capacitor step sizes

- Get visibility of the actual capacity of the APFC panel factoring in loss of capacitance due to ageing

- Prevent premature loss of capacitance through proactive temperature management

Power Quality analysis

- Know whether the current APFC panel has the capacity to meet the required reactive power (kVAR) demand

- Identify key loads contributing to the THD

- Identify requirement of filters

- Monitor performance before and after filter installation

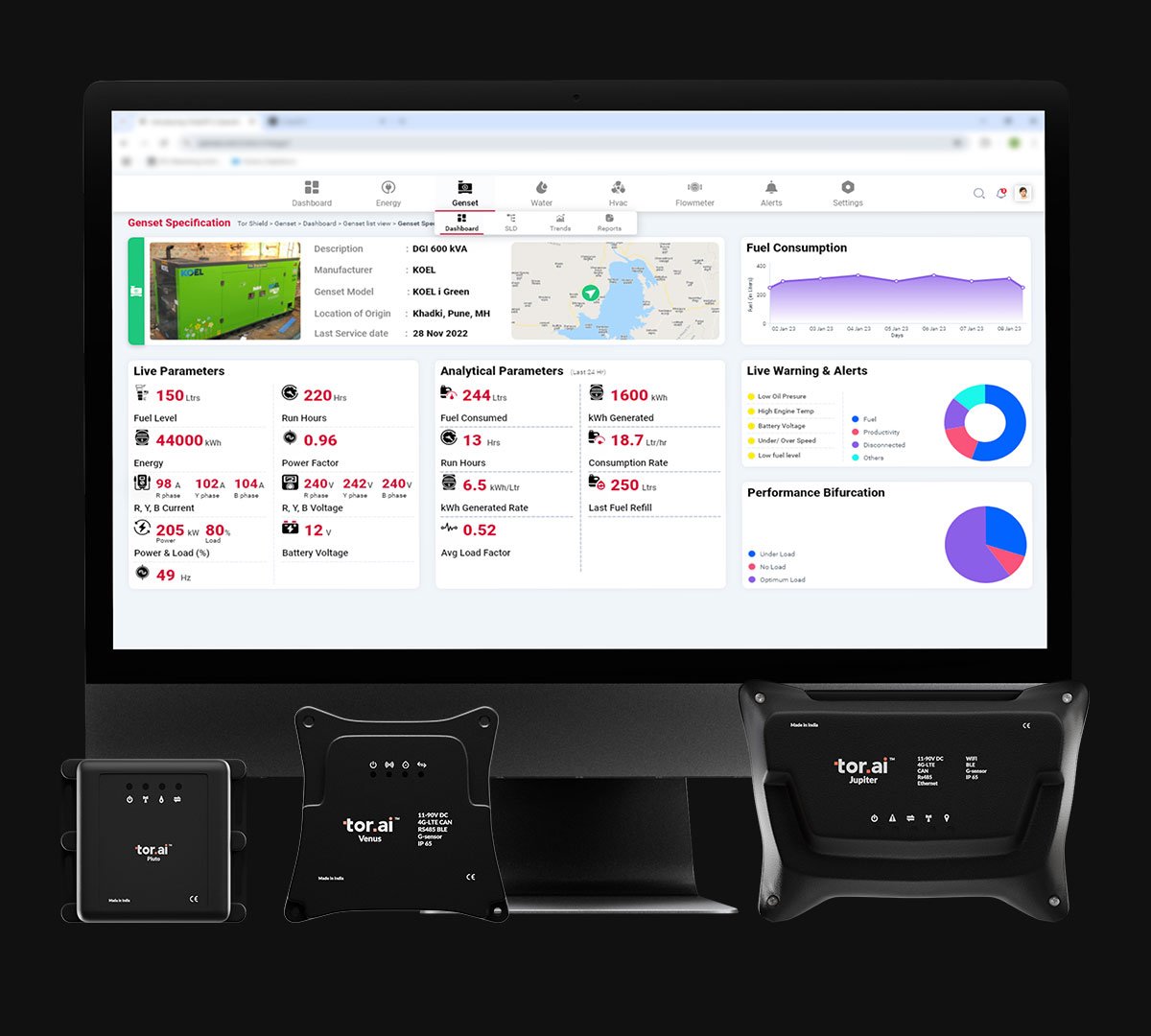

Architecture

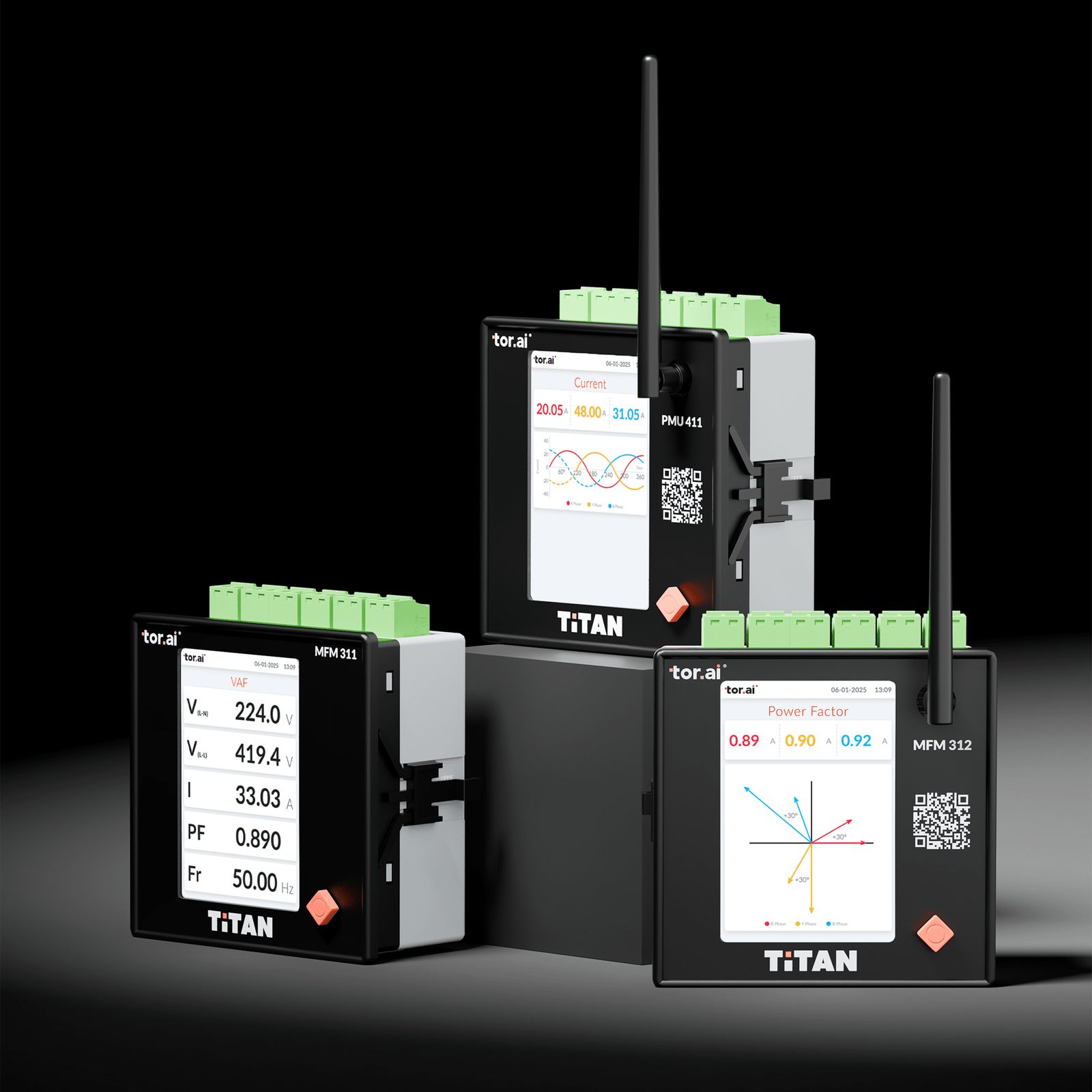

Energy Meters

Tor Titan is a compact power monitoring unit that tracks 68 electrical parameters, including power quality and harmonics, with advanced transient analysis. With advanced connectivity, scheduling, and PLC functionality, it integrates seamlessly into industrial IoT systems for efficient and reliable performance.

Temperature sensors

Tor Mercury is a high-temperature, long-life wireless sensor built for extreme environments. It is suitable for temperature monitoring of bus bar trunking & distribution panel systems. Its 240°C resilience, 15-year battery life, and BLE connectivity enable seamless IoT integration, faster installations, and reliable performance with minimal maintenance.

Gateways

Industrial application device having 4G LTE Cat1 connectivity with flexible communication protocol support and flexible Inputs along with a high capacity battery backup