Busbar Trunking Monitoring Solution

Assets We Track

- Busbars

Cost Reduction

- Alerts for busbar joints temperature threshold

- Realtime monitoring of busbar joint temperature and humidity.

Manpower optimization

- Automated real-time data acquisition

- Real time visibility of busbar trunking system

Enhanced safety

- Busbar trunking temperature monitoring and thermography

- Humidity alerts

Downtime reduction

- Error free data logging

- Spotting early failures

- Predictive maintenance

- Resource planning (Spare parts, maintenance manpower)

Quick issue identification

- Bird’s eye view of multiple locations / assets on single screen

- Comparative trend analysis

Efficient MIS / reporting

- Joint wise thermography reports

- Benchmarking across locations / assets

Enhanced response time

- Whatsapp / Email alerts for all deviations

- Push notifications

- Flexibility to set deviation levels for alerts / warnings

- Quick RCAs through INVESTIGATE feature

Our innovative Busbar trunking monitoring solution offers comprehensive approach to proactively manage the health of your Busbar joints which are receptive for failures.

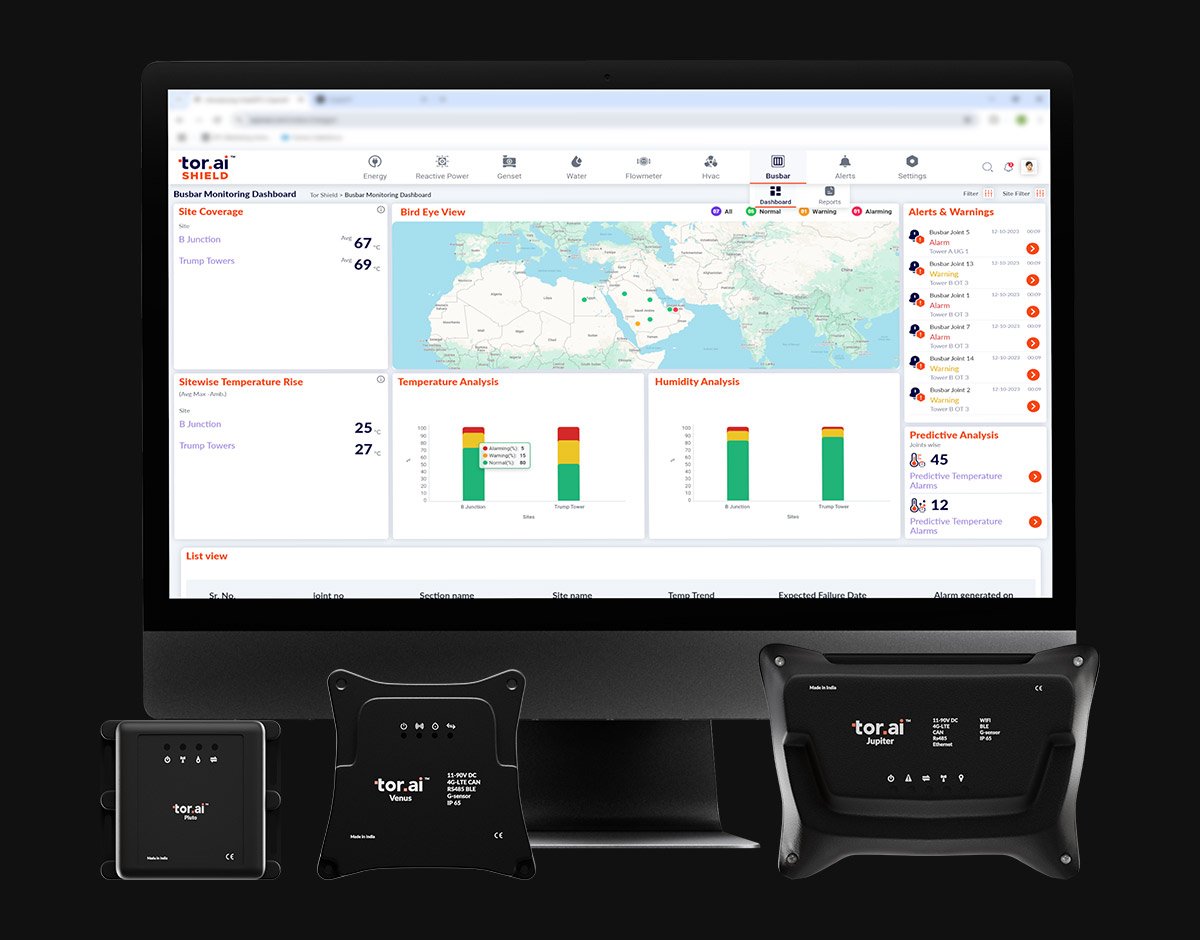

Key Features

Proactive busbar joints monitoring

- Realtime busbar joint temperature and humidity monitoring

- Monitor multiple sites in a single dashboard

- Drill down view of every level with live parameters

- Quickly identify abnormalities with color codes.

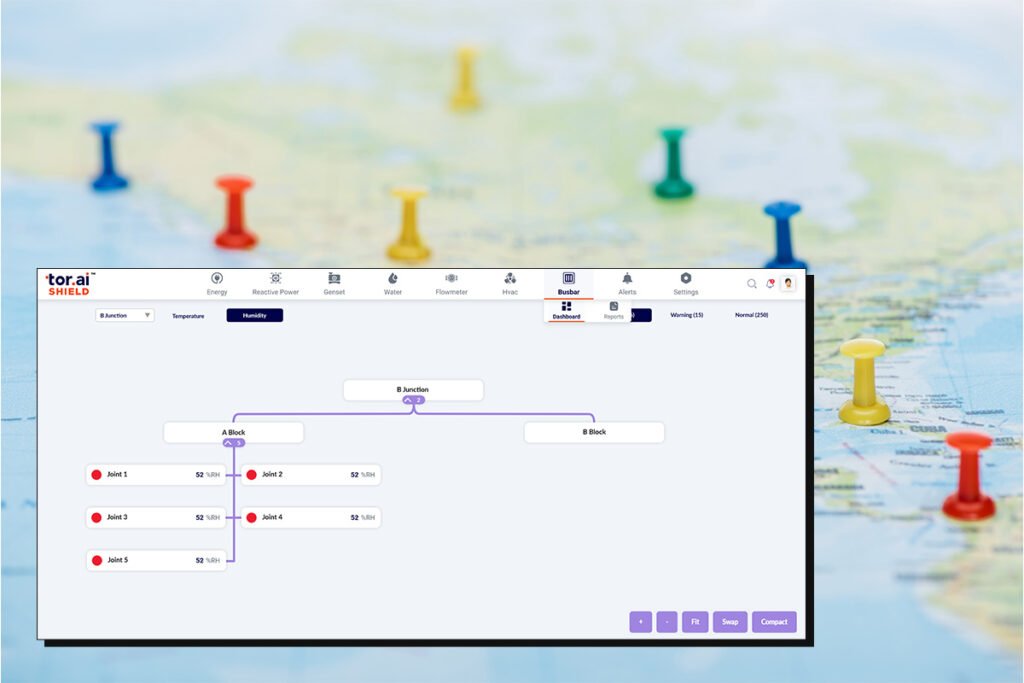

Hierarchal view of every site

- Every site is divided into multiple sections

- Each section has multiple busbar joints

Trend analysis and predictive maintenance

- AI-based engine to predict joint failures

- Estimation of time to failure

- Time series analysis of critical parameters.

- Add on Shield Energy module to co-relate joint temperatures with current

Reports and Alerts

- Thermography reports

- Parameter and site-wise history (data populated per minute)

- Digital logbook

- WhatsApp/email alerts based on user hierarchy

- Front end configuration of mobile numbers and email IDs

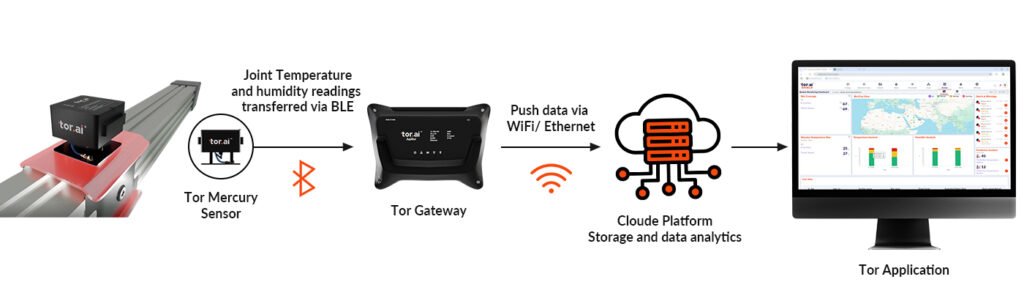

Architecture

Temperature sensors

Tor Mercury is a high-temperature, long-life wireless sensor built for extreme environments. It is suitable for temperature monitoring of bus bar trunking & distribution panel systems. Its 240°C resilience, 15-year battery life, and BLE connectivity enable seamless IoT integration, faster installations, and reliable performance with minimal maintenance.

Gateways

Industrial application device having 4G LTE Cat1 connectivity with flexible communication protocol support and flexible Inputs along with a high capacity battery backup