Our Process

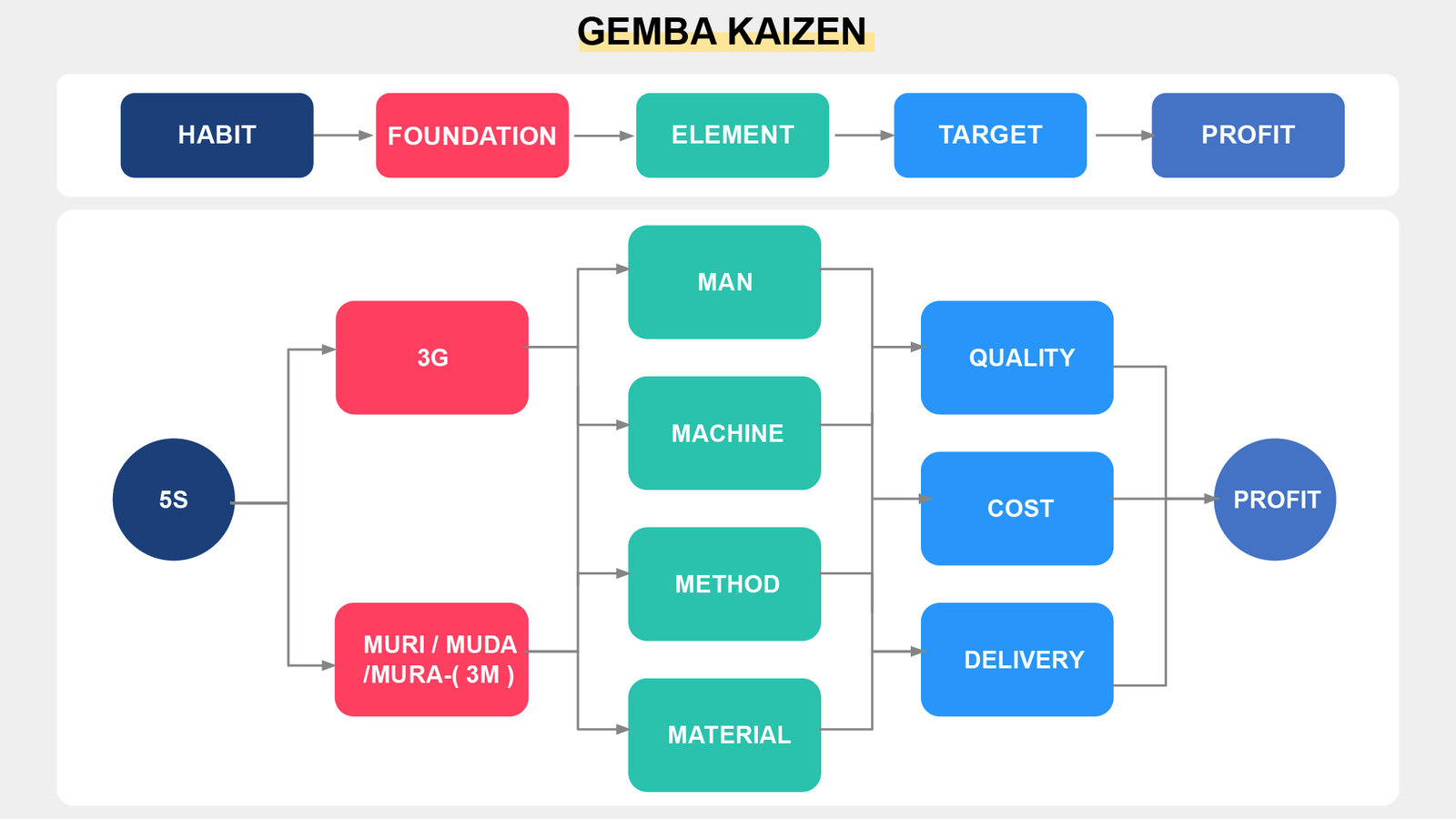

Our Goal-Achieving Approach is a strategic planning framework that translates a company’s overarching objective into a structured hierarchy of actionable steps. It consists of five key processes designed to foster habit formation, optimize resource utilization, and leverage core capabilities — all aimed at achieving targeted outcomes and maximizing profitability.

JMJ Zencraft’s Goal-Achieving Approach

Under the aegis of our founding father, Mr. SK Banerji, we work from the grassroots level.

An organization’s methods and practices aren’t simply isolated events, rather they are its core habits. Since organizations are made up of people first, meaningful and lasting change must start with them. We train employees to develop habit loops around key behaviors such as management, continuous improvement, and willpower—helping to embed the organization’s core principles into daily actions. These people-centered habits reflect the philosophy of LEAN, empowering frontline staff with the capabilities they need to adapt, persist, and drive sustainable change.

Eliminating all forms of waste is essential to achieving operational efficiency. By identifying and removing waste—specifically Muri (overburden), Muda (non-value-adding activities), and Mura (unevenness)—we enhance quality, safety, and overall productivity while building more sustainable processes. To support this, we apply the 5S LEAN tool: Sort, Set in order, Shine, Standardize, and Sustain. This structured approach helps declutter the workplace, paving the way for improved organization, planning, and continuous improvement.

Every outcome has a cause, and inefficiencies or redundancies within an organisation can often be traced back to the 4Ms: Material, Method, Machine, and Man. These four factors are frequently at the root of operational discrepancies, ultimately leading to significant economic loss. Our focus is on deeply analyzing these 4Ms as potential sources of variation and inefficiency. By understanding and stabilizing them, we lay a solid foundation for continuous improvement and long-term operational excellence.

While many companies believe it’s impossible to simultaneously improve quality, reduce costs, and shorten delivery times, we firmly believe that all three can be achieved together. By eliminating non-value-added activities, embracing flexible manufacturing, and implementing just-in-time scheduling and production, we create efficient systems that deliver high quality, cost-effectiveness, and timely delivery—without compromise.

With the right tools and practices, we focus exclusively on value-added activities, eliminate all forms of waste, and drive continuous improvement through standardization. Our approach helps you build an adaptable business model that operates at peak efficiency—delivering maximum value to your clients and customers.