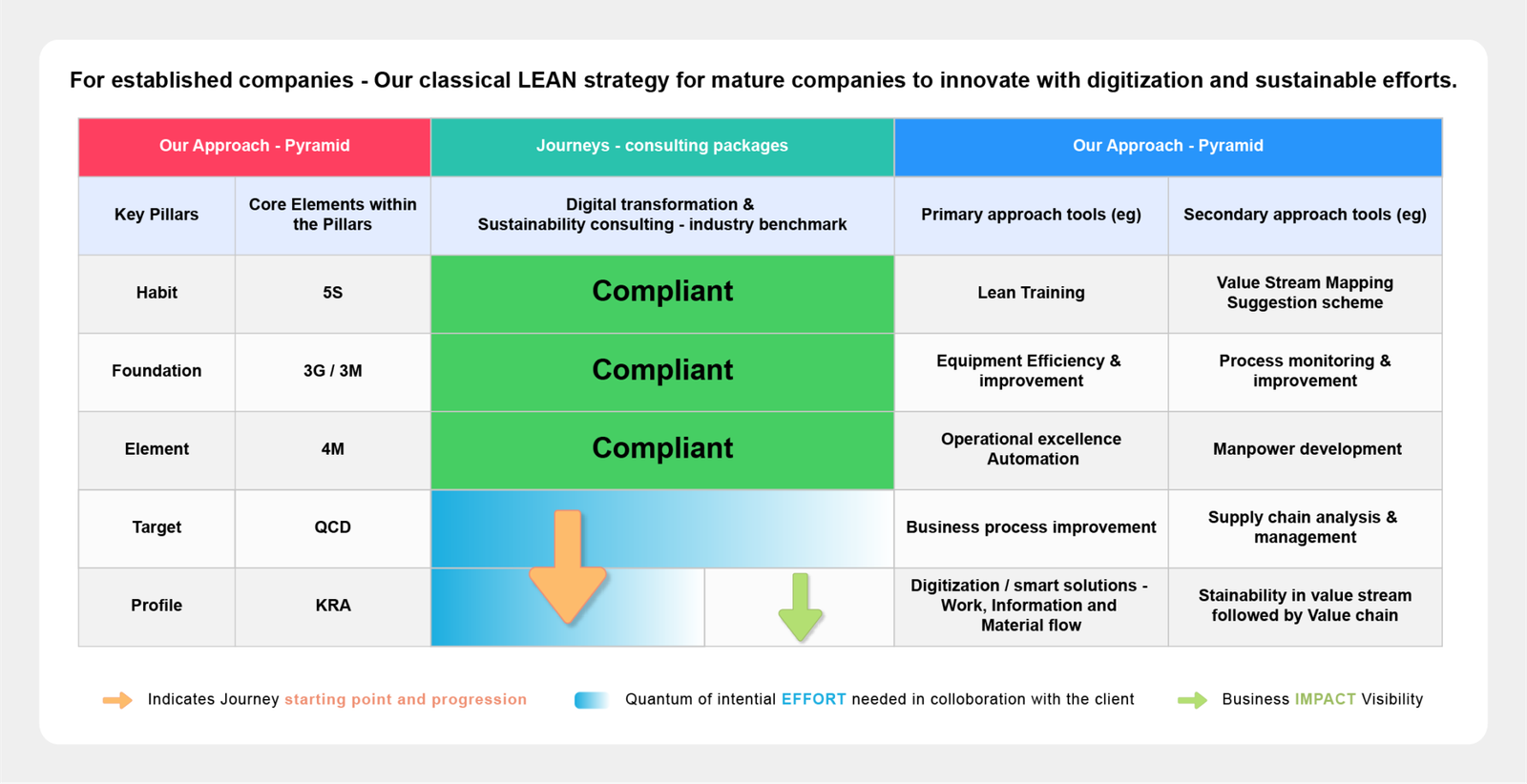

Digital Transformation & Sustainability Consulting

In a rapidly evolving market, digital transformation is essential. By leveraging a certain level of Statistical Process Control (SPC), we combine LEAN principles with data and AI to eliminate waste (Muda, Mura and Muri), optimize operations, and modernize legacy systems. Using the PDCA cycle, we drive sustainable improvements through digitization, automation, and enhanced equipment efficiency for long-term organizational agility and growth.

PLAN: Laying the Foundation for Transformation

At this stage, we design targeted initiatives to drive successful digital transformation aligned with your business goals. We develop a comprehensive digital strategy that defines priorities, key deliverables, desired outcomes, and implementation timelines.

- Current State Mapping (CSM): Our process begins with creating a Value Stream Map (VSM) of your organization’s current state. This allows us to pinpoint inefficiencies, identify digitization opportunities, assess available and required resources, and understand gaps in information flow, material handling, and workflow processes.

- Gap analysis: Next, we conduct a thorough gap analysis to compare the current state with the ideal LEAN digital state. Using feasibility studies, we evaluate process value contributions, identify what can be optimized or replaced, and determine the need for OT data integration. We then design a framework to collect and aggregate data in a secure, simplified, and analytics-ready format.

- Future State Mapping (FSM): Based on the gap analysis, we outline a detailed roadmap that defines the step-by-step blueprint for digital implementation—guiding your enterprise from the current state to the desired future state.

DO: Executing the Transformation Plan

The second step is the implementation phase. Once improvement areas are identified, we begin executing targeted initiatives based on the roadmap to unlock measurable value.

- Business Process Improvement: We deploy tailored LEAN tools in synergy with software and AI to streamline and optimize core business processes.

- Performance Monitoring & Improvement: By tracking key performance indicators, we cultivate a culture of continuous improvement. Leveraging Kaizen, we guide organizations toward achieving peak performance.

- Equipment Efficiency Improvement: We work to enhance the productivity of manufacturing equipment, aiming to boost overall process efficiency and reduce operational costs.

- Digitization and Automation: We integrate automation technologies to detect and correct defects while improving workflows. Our approach combines LEAN principles with digital tools to empower data-driven decision-making and operational excellence.

CHECK: Measuring and Controlling Performance

In this phase, we assess and regulate processes and operations using our comprehensive 4T Program, which includes:

- TQM – Total Quality Management

- TQC – Total Quality Control

- TPM – Total Productive Maintenance

- TPS – Toyota Production System

This integrated approach ensures consistent quality, operational efficiency, and sustained performance improvements.

ACTION: Standardizing and Sustaining Improvements

At this stage, we implement targeted Corrective and Preventive Actions (CAPA) to standardize and enhance processes. These actions are executed through:

- Performance Monitoring & Improvement

- Equipment Efficiency Optimization

Once improvements are realized, we focus on sustaining them through a culture of continuous improvement, ensuring long-term success and operational excellence.